Quoting an electrostatic powder coating project may seem complicated if you are not familiar with the process. However, once you understand the basic factors that affect the cost, you will be able to request a fair quote, compare suppliers, and avoid unexpected charges.

In this article, we explain step by step, in simple terms, how an electrostatic powder coating project is quoted and what information you should have ready.

What Is Electrostatic Powder Coating? (Quick Overview)

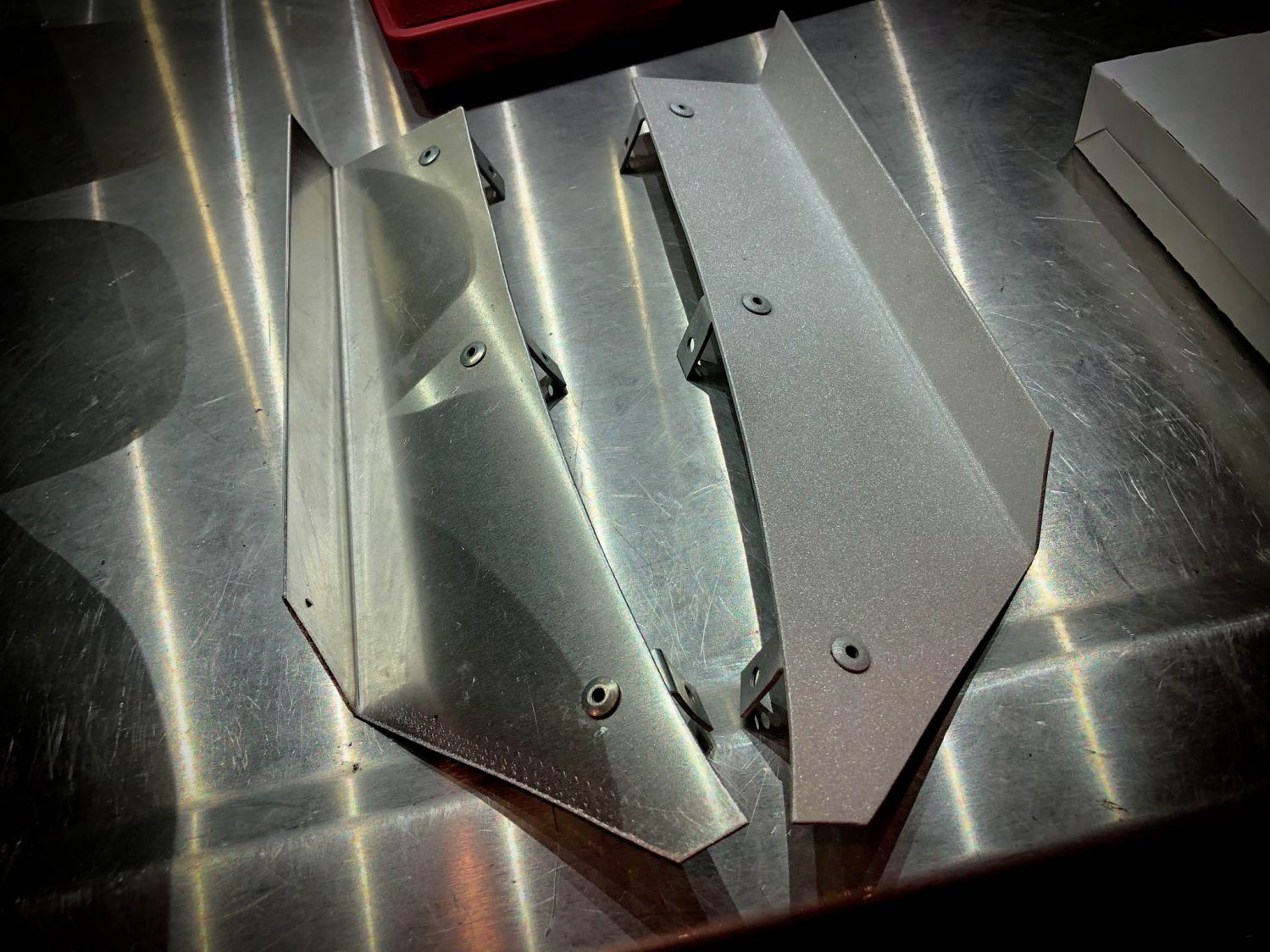

Electrostatic powder coating is an industrial finishing process where powdered paint is applied to metal parts using an electric charge and then cured in an oven. The result is a uniform, durable, and high-resistance finish, commonly used for metal structures, racks, furniture, machinery, frames, and industrial components.

1. Part Dimensions: The Starting Point

The most important factor in a quote is the size of the part.

Powder coating prices are usually calculated by:

- Square meter (m²)

- Or price per part, based on its total surface area

To calculate the area, all dimensions are considered:

- Height

- Width

- Length

🔹 Simple example:

A part that measures 1 m × 0.5 m × 0.3 m is not quoted only by the front face, but by all its surfaces.

The larger the surface area, the more paint, time, and energy are required.

2. Quantity of Parts

It is not the same to coat:

- 10 parts

- 100 parts

- 1,000 parts

For larger volumes:

- Oven and labor usage is optimized

- Time per part is reduced

- The unit cost is usually lower

That is why higher quantities often result in better pricing per piece.

3. Condition of the Material (Very Important)

Before painting, the metal must be properly cleaned and prepared. There are usually three scenarios:

- New and clean parts

- Parts with grease, dust, or dirt

- Parts with rust or old paint

Each condition requires different levels of preparation, which affects the final cost.

🔹 Key point:

Proper pretreatment ensures better paint adhesion and longer coating life.

4. Type and Color of Paint

Not all powder coatings cost the same. Prices may vary depending on:

- Color (some special colors are more expensive)

- Finish (matte, gloss, textured)

- Indoor or outdoor use

- Required coating thickness

Some clients:

- Request a specific RAL color

- Supply their own paint

- Or allow the supplier to include the paint in the quote

All of this should be defined before pricing the project.

5. Who Supplies the Paint and Transportation?

This point can significantly change the final cost.

It must be clearly defined:

- Does the supplier include the paint or does the client provide it?

- Are the parts delivered to the facility?

- Is transportation included or excluded?

When the client provides the paint and transportation, the price may be lower, but the supplier is still responsible for labor, energy, equipment, and technical expertise.

6. Lead Time and Urgent Jobs

If the project requires:

- Express delivery

- Work outside normal operating hours

- Priority over other jobs

An additional charge may apply, as it affects production planning and resources.

7. How a Powder Coating Quote Is Usually Presented

A clear and professional quote typically includes:

- Description of the parts

- Dimensions or total surface area

- Quantity of parts

- Price per square meter or per part

- Scope of work

- What is included and what is not

- Estimated delivery time

This helps ensure that both parties have clear expectations.

Conclusion

Quoting an electrostatic powder coating project is not just about assigning a price. It involves analyzing:

- Part size

- Quantity

- Material condition

- Type of paint

- Logistics and delivery time

The more accurate information you provide, the more precise and fair the quote will be.

If you are planning to powder coat metal parts, always ask questions, compare options, and make sure you understand what the service includes, not just the final price.