In electrostatic powder coating, the electrode is one of the most critical components of the spray gun. Although it may look like a simple spare part, its type, condition, and correct application have a direct impact on:

Electrostatic charging efficiency

Powder adhesion

Final surface finish

Powder consumption

Process stability

Choosing the right electrode for the right application can be the difference between a professional finish and coating defects.

What Is the Electrode in an Electrostatic Spray Gun?

The electrode is the component responsible for generating and transmitting the electrical charge to the powder particles, allowing them to be attracted to the grounded metal part.

Depending on its shape and design, the electrode controls the intensity of the electrostatic field and the way the powder is deposited.

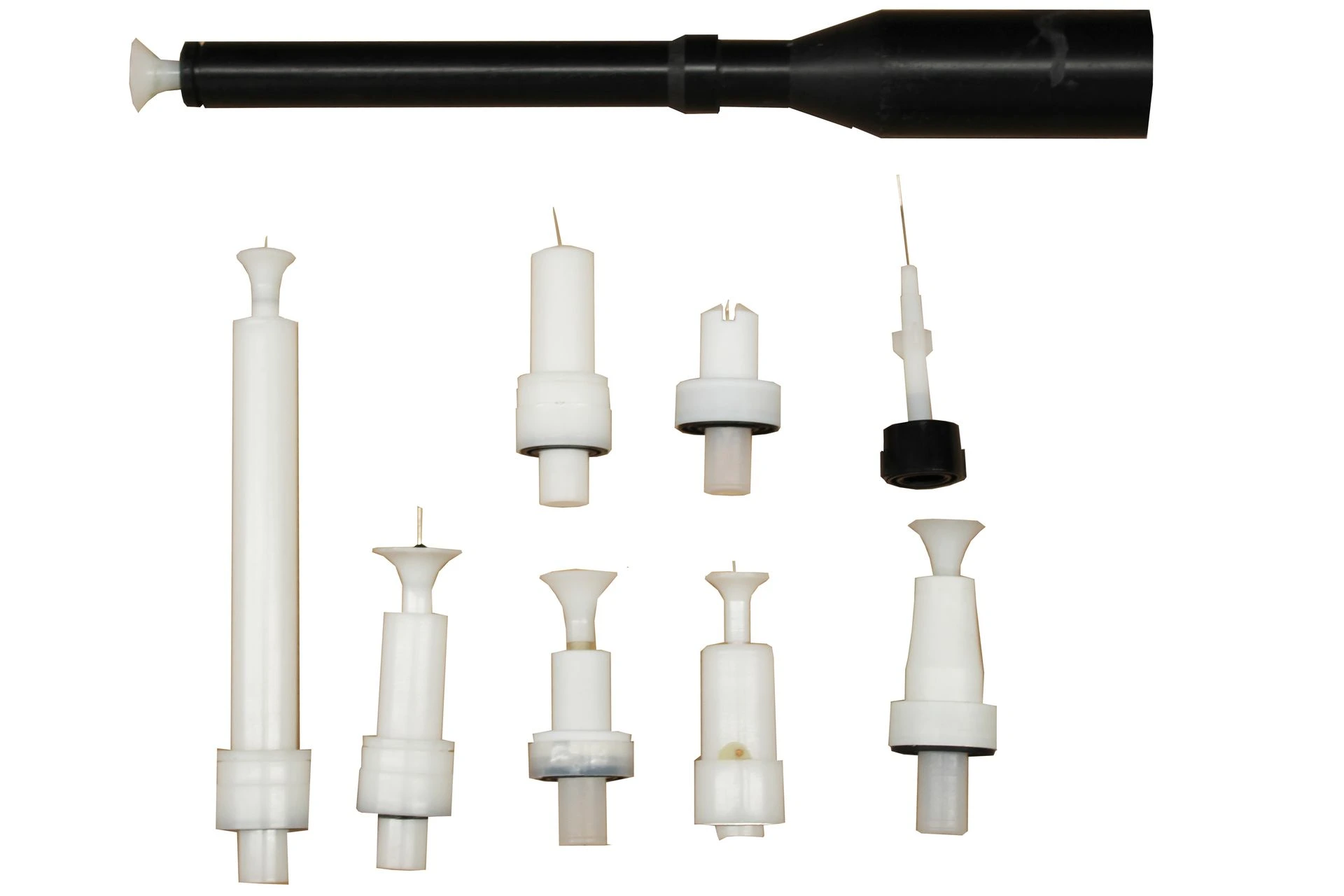

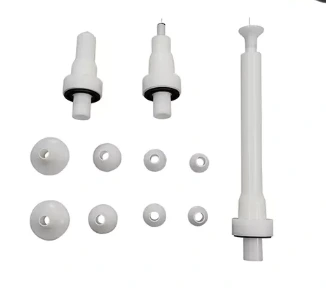

Most common electrode types and when to use them

🔹 1. Needle electrode

The most commonly used for general applications

Characteristics:

Fine tip

Concentrated electrostatic field

Excellent charging efficiency

When to use it:

Flat parts or simple geometries

Continuous production

When maximum powder transfer efficiency is required

Advantages:

High performance

Less paint waste

Ideal for standard industrial coating lines

🔹 2. Flat or disc electrode

For smoother and more controlled finishes

Characteristics:

Wider, less aggressive electrostatic field

Reduced point ionization

When to use it:

Delicate parts

Final coats

When a more uniform finish is required

Advantages:

Reduces “orange peel” effect

Better control on visible surfaces

🔹 3. Star-type electrode

Designed for complex geometries

Characteristics:

Multiple ionization points

More uniform distribution of the electric field

When to use it:

Parts with holes, recesses, or complex shapes

Profiles, racks, tubular structures

Advantages:

Better powder penetration

Reduces uncoated areas

🔹 4. Internal charge electrode

High efficiency with reduced Faraday cage effect

Characteristics:

Charge is generated inside the gun body

More controlled electrostatic field

When to use it:

Deep cavities

Enclosed parts

Applications where the Faraday effect is a problem

Advantages:

Better internal coverage

More uniform finish in hard-to-reach areas

When should an electrode be replaced or inspected?

It is recommended to inspect the electrode when you notice:

Loss of adhesion

Increased powder consumption

Sparking or unstable discharge

Uneven finishes

Excessive powder buildup on the gun

A worn or dirty electrode drastically reduces the efficiency of the electrostatic system.

Practical recommendations

✔ Use the correct electrode type according to the part geometry

✔ Keep electrodes clean and free of powder buildup

✔ Replace the electrode if it shows wear, corrosion, or deformation

✔ Use spare parts compatible with your gun modela

Conclusion

Not all electrodes are suitable for every application. Choosing the right electrode at the right time improves finish quality, reduces costs, and increases the productivity of your electrostatic powder coating line.

If you are unsure which electrode to use, or if you need spare parts for your gun, having proper technical guidance can save you time, powder, and rework.